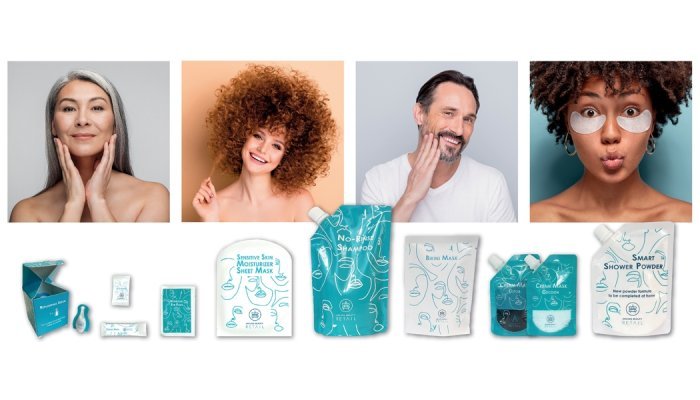

Arcade Beauty continues to innovate with two main goals: the reduction of the environmental footprint of their products and the expansion of their lines of turnkey products in retail sizes.

Multiple skills

“The sampling industry has recorded a dramatic transformation over the past few years. Two-dimensional flat formats have largely evolved into much more premium 3D formats. For the group, this involved a huge evolution of our know-how and our technologies,” explains Carl Allain, the Group’s CEO.

“While cheap, mass sampling remains a key tool for global launches, it is now completed by more targeted and more premium campaigns. As a result, the technical difference between sampling and retail products is becoming increasingly thin,” he adds.

Today, Arcade Beauty still generates 80 % of its revenue from the samples sector, compared to 20 % from retail-size products. But this average figure masks important regional disparities for a group that has production units in Europe, China, Brazil, and the United States. Arcade’s Brazilian subsidiary, for instance, generates 80 % of its turnover in the manufacture of turnkey products intended for retail sale.

For Laurent Oulès, the new General Manager of the Europe branch, this transformation of the business has been made possible thanks to large varieties of in-house technological skills.

“From printing to filling, Arcade Beauty’s five European factories are operating within some forty essential technological scopes to produce the full diversity of samples used by the beauty industry. And each year we bring new skills to the group,” he underlines.

New materials

Especially since the transformation of samples and packaging continues with the aim of increasing their content in recycled and recyclable materials.

“For many flexible pouches, we are moving to mono-PE solutions. PE is an easily recyclable material, but this shift requires that we adapt our production processes,” explains Laurent Oulès.

Beyond recyclable single-material solutions, Arcade Beauty is also striving to reduce the plastic content in their sampling and packaging solutions, either by using mixed materials containing a portion of paper (flexible pouches with 63% of paper, secondary packaging with 90% of paper), or by developing 100% paper-cardboard solutions (a shift that is facilitated by the rise of anhydrous, solid or powder formulas).

At Paris Packaging Week, Arcade presented PaperSnap, an evolution of the EasySnap solution containing 80% paper.

Even if it poses technical difficulties in terms of barrier effect and regarding the product’s lifespan, the transition to paper is an important step in reducing the environmental footprint, believes Claudie Guérin, Global CSR Director at Arcade Beauty.

“Carbon emissions of flexible pouches made from a material containing a portion of paper are more than 50% lower than those of conventional flexible pouches. On some secondary packaging, adding paper can lead to a reduction by up to 80%,” she explains.

New fragrance offering

In addition, Arcade Beauty continued to diversify its offering of retail-size products. At the last edition of Paris Packaging Week, Arcade thus presented several scented innovations created within the group’s fragrance formulation laboratory in the USA: three new alcohol-free formulas (a Silky Gel, which comes in a bottle with applicator, a Perfume Oil, housed in a dropper pack, Stick-to-Powder cream) and two formulas with alcohol (a Body Mist and a Hair Mist, which both come in pump bottles).

“These formulas, which are fully customizable with the customer’s concentrate, are in line with the clean perfumery trend and offer innovative gestures in line with consumer expectations,” concludes Candice Jagut, VP Marketing, Innovation & Retail, at Arcade Beauty.